Understanding Pressure Measurement

Pressure measurement is all about PSI. That’s because pounds per square inch (PSI) is the most common unit for measuring pressure in the U.S. It’s important to understand what PSI means and how it is used.

PSI (pounds per square inch) is the unit of pressure used the vast majority of the time in the United States for household, commercial, or industrial equipment. Other countries measure pressure in different units. In scientific contexts (physics labs and so forth), pressure is typically measured in much smaller units called pascals (named after French physicist Blaise Pascal). For reference, 1 PSI equals 6,894.76 pascals. Pressure measurement instruments such as pressure gauges and sensors typically display measurements in PSI. Two frequently used variations of PSI are PSIA and PSIG.

Pounds per Square Inch Gauge – PSIG Vs. Pounds per Square Inch Absolute – PSIA

PSIG is the term for pressure specified by a gauge or other pressure measurement device. It gives the difference between the pressure in a pipe or tank and the pressure of the atmosphere (atm).

PSIA is a term that describes the absolute pressure in PSI, including the pressure of the atmosphere. Absolute pressure is also sometimes referred to as “total pressure.”

Examples of How to Calculate PSIG and PSIA

Note that PSIG is always lower than PSIA. The formulas to describe the relationship are: PSIG + 1 atm = PSIA and PSIA – 1 atm = PSIG (where atm is atmospheric pressure). It is easy to calculate PSIA or PSIG or convert between the two. You can use the actual atmospheric pressure value for your location if it is available, or you can also use 14.7 psi (the approximate atmospheric pressure at sea level) as a standard value to convert PSIG to PSIA and vice versa. (Unless you live at high altitude or in a deep valley, the sea level value will work.) In other words, since atmospheric pressure at sea level is 14.7 PSIA, you subtract the PSIA of 14.7 from an atm pressure of 14.7 to equal zero PSIG (14.7 (PSIA) – 14.7 (atm) = 0). As an example, absolute pressure at sea level is 14.70 PSIA and absolute pressure at an elevation of 1,000 feet is 14.18 PSIA. At the higher elevation there is less pressure, so if an absolute pressure gauge is read at a 1000-foot elevation, its readings will be close to .5 PSI (14.70 – 14.18 = .52) less than those from a standard pressure gauge.

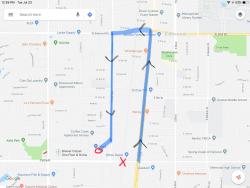

ROAD CONSTRUCTION DETOUR MAP!

ATTENTION - 15th Street in Edmond West of Broadway Extension will be closed from Tuesday, Jul 23rd, to Friday, July 26. Please see the attached map for directions to our laboratory.

- From Oklahoma City follow Broadway past 15th Street

- Turn Left (West) at the stop light onto 2nd Street

- Follow 2nd Street under the train tracks

- Turn Left (South) at the light onto Fretz AVENUE.

- Note that Fretz AVENUE is a 25 mph speed zone much of the way. (This is a massive revenue street for the city!)

- Jog Right (Southwest) onto Fretz DRIVE.

- Arrive at the Laboratory on the Right (West) Side of the road. (The red circle on the map)

Should you calibrate your new equipment?

Does newly purchased equipment require calibration? The short answer is “yes.” (May we suggest you consider drop shipping new equipment to our laboratory for calibration.) We field this question quite often. Relax and read no further unless you need to know the reasons why.

Often, we are asked this question by a time-pressured technician in a desperate voice who has just purchased new replacement equipment to remedy a work delay. And just as often, before we can answer the first question, we are also hypothetically asked, “This equipment is brand new. Surely it is good, or it would have failed quality checks before it left the factory. I really don’t need to waste money having this calibrated, do I?”

Unreservedly, the answer is still “Yes, you need to calibrate your new equipment” even though the cost of calibration is not the real issue, it is the time cost of work delays. The stressed-out technician has made a couple of huge assumptions: (1) the supplier checked the equipment before it was shipped, and (2) the quality check was reliable. Neither of these situations is guaranteed to be true. Even though much new equipment contains a slip of paper with a number stamped on it that broadly states “Inspection Passed,” further reading will also say the equipment is limitedly warrantied against manufacturing defects. Read on, the manufacturer will only cover the cost of replacing the unit purchased. These sheets of paper are not “Certificates of Calibration” or “Calibration Reports.”

Keep in mind, many instruments are manufactured by unknown companies irrespective of what brand name they carry in your market, perhaps in jurisdictions with different standards allowing for errors much wider than the buyer’s. New measuring equipment is frequently placed into service straight from the box, most often with few problems. But that piece of paper with the comforting “Passed” stamp—it is free to the buyer, but when the user discovers an issue, the remedy will be far from free.

Drop ship your purchased equipment directly to our laboratory for a quick turnaround!

48 Hour Calibration: 30% Expedited Service Fee

Next on Bench Calibration: 40% Expedited Service Fee

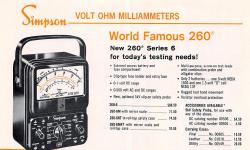

Amp Clamp Calibration

Calibrating Your Amp Clamp Meters

Clamp on ammeters (also known as Amp Clamps, Clamp Meters and Current Clamps) are used to measure electrical current flowing through conductors. They clamp around conductors allowing the user to measure current without breaking into the circuit. In addition to current, most clamp meters typically measure voltage, resistance, continuity and other functions commonly found in a digital multimeter.

Rest assured that HDCL will test multiple points across the range of your clamp meter and each measurement function. For more information please give us a call or submit an online quote request.

As always, we strive to calibrate your equipment and return it to you as quickly as possible. Our standard lead time is 5 to 7 business days.

If you need your equipment returned even more quickly than our standard lead time, just let us know. We offer two expedited services.

48 Hour Calibration: 30% Expedited Service Fee

Next on Bench Calibration: 40% Expedited Service Fee

Expedited Service for Your 2020 Calibrations

HDCL OFFERS TWO LEVELS OF EXPEDITED SERVICE! Click here to learn more.

We know how important your equipment and tools are to you. They are your livelihood. At HDCL we also realize that scheduling annual calibration is only part of your job. Rest assured, it may be part of your job but it is all of our job! We strive to calibrate your equipment and return it to you as quickly as possible. Our standard lead time is 5 to 7 business days.

If you need your equipment returned even more quickly than our standard lead time, just let us know. We offer two expedited services.

48 Hour Calibration: 35% Expedited Service Fee

Next on Bench Calibration: 50% Expedited Service Fee